Tomag Your partners in precision mechanics

Specialized in design and precision mechanical machining, we have been collaborating for 20 years with some of the most important companies in the eno-mechanical and industrial sector.

Thanks to the experience gained in important projects, TOMAG today offers cutting-edge technology that allows us to design and produce various types of components, always maintaining a high level of precision and accuracy.

The company, which is based in Canelli, a leading city in the wine sector and in the eno-mechanical industry, has distinguished itself and has acquired prestige for the production of some components required by manufacturers of filling and capping machines.

Our history

Founded in 2001 at the behest of Totino Sebastiano, who after years of experience in the sector decides to set up his own business, in 2014 TOMAG passes in management to his son Gianluca, already operating as a draftsman and technical designer following his diploma.

Thanks to a dynamic team of technicians with different specializations, we are now able to produce and offer assistance in every mechanical sector.

Manufacturing

from Cad to maintenance

We carry out the ideas of our clients by creating and designing independently, with the possibility of making every type of mechanical component starting from a CAD project.

We also propose to:

Maintenance and Repairs

Assemblies

Welds

As a guarantor of the quality of our work, there is the experience gained over years of collaboration with the most varied Piedmontese industrial realities.

The use of parallel lathes and traditional milling machines, together with numerically controlled machinery, allows TOMAG to meet "tailor-made" needs with speed, flexibility and precision, elements particularly appreciated by small and medium-sized industries, which represent most of the Italian industries.

Production

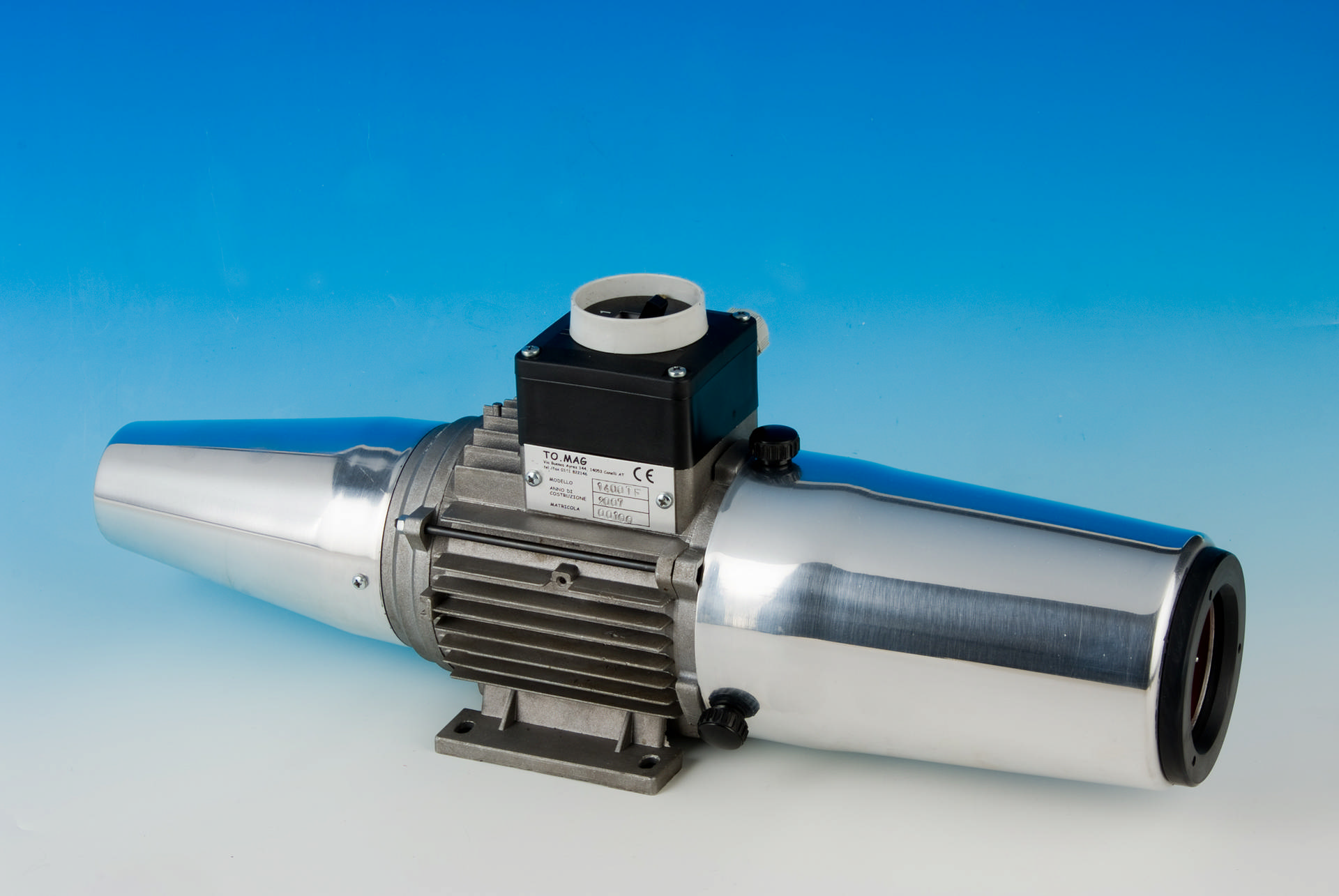

Rolling and capping machine

- Rolling and capping machine for aluminum,, tin-foil and poly laminate caps.

- It can be supplied with a pre-sleeking unit.

- The capping machine can be applied on automatic machines.

- Cap sizes: max diameter 38 mm max length 65mm 55mm with pre-sleeking

- Table version

- Motor rotation speed. 1400 or 2800 r.p.m.

- Electrical requirements: 220V -380 V – 50 Hz. (different ones on request)

Models

- MF motor rotation speed 1400 voltage 220/240 Volt 50 Hz

- TR4P motor rotation speed 1400 voltage 380 Volt 50 Hz

- TR2P motor rotation speed 2800 voltage 380 50 Hz (special voltage on request)

TT Thermal Head

Testata Elettrica

- For retractable capsules on flush cap bottles.

- Heat regulator.

- It can be applied on a labeling machine

- Weight Kg. 6

- Table version

Power 1200 watt

Voltage 220/240 v 50 hz (special voltage on request)

Dimensions diameter of the resistance 74 mm

Completely in stainless steel

Possibility of central ventilation

TG Thermal Head

Testata Elettrica

- For retractable capsules on flush cap bottles.

- Heat regulator.

- It can be applied on a labeling machine

- Weight Kg. 6

- Table version

Power 1200 watt

Voltage 220/240 v 50 hz (special voltage on request)

Dimensions diameter of the resistance 74 mm

Completely in stainless steel

Possibility of central ventilation

TF Thermal Head

Testata Elettrica

- For retractable capsules on flush cap bottles.

- Heat regulator.

- It can be applied on a labeling machine

- Weight Kg. 6

- Table version

Power 1200 WATT

Voltage 220/240 V 50 Hz (special voltage on request)

Completely in stainless steel

Possibility of central ventilation

Dimensions diameter of the resistance 90 mm

Contacts

Tomag SRL

FRAZIONE BOIDI, 53/A, 14042, Calamandrana (AT)

P.IVA IT01675070054

E-mail: totino@tomag.it

Tel: +39 0141 822146